Full Truck Load Shipping Service

Take the shortest path when shipping your goods, quickly, smoothly and safetly.

WHY FR8APP

100% Trusted Carriers

No driver shortage here.

We prescreen each carrier on multiple criteria to make sure they operate up to our high standards, so your matched driver will always be trustworthy and ready to carry your load. Safety checks include safety record, authority, insurance and references.

Cost Transparency

Feeling sticker shock with hidden carrier fees?

Fr8app’s fixed rates means you know exactly what is paid to the carrier and to us, for each job, and what to expect for future jobs. No hidden fees when using our marketplace!

Safety & Reliability

Worried about the cross-border journey?

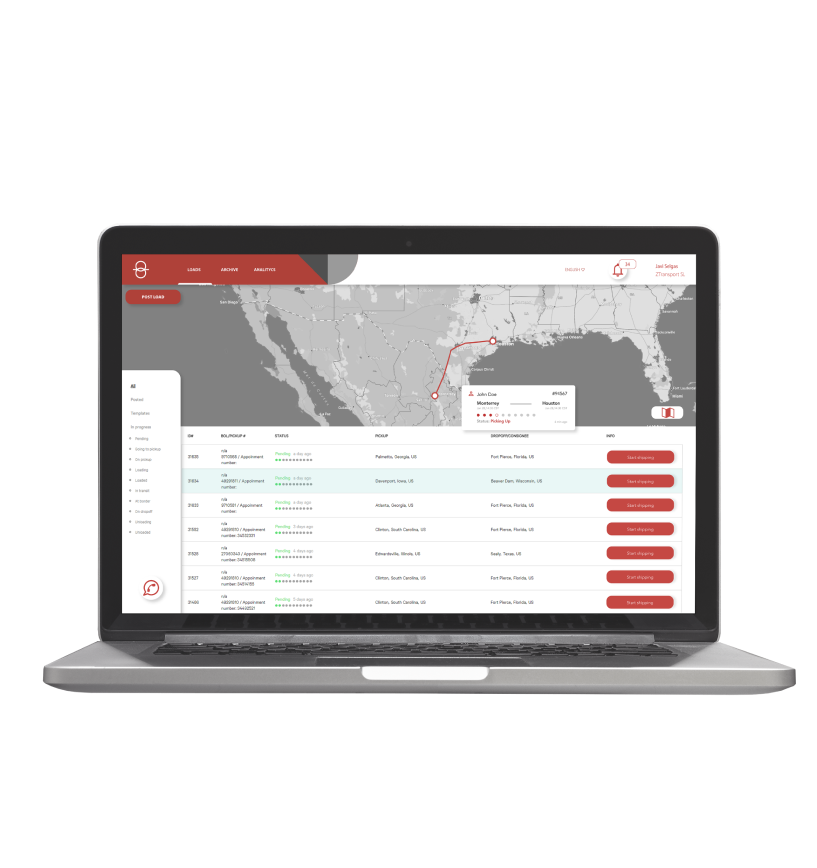

Live 24×7 GPS tracking on mobile app or on desktop, as well as a chat to keep you in direct and constant communication with the carrier and our team.

Ease to Use Platform

Is your current solution outdated?

Our cloud-based platform delivers one easy-to-use centralized location for visibility into all of your loads. As a fully scalable tool, it can integrate into existing TMS solutions or serve as its own robust ERP solution.

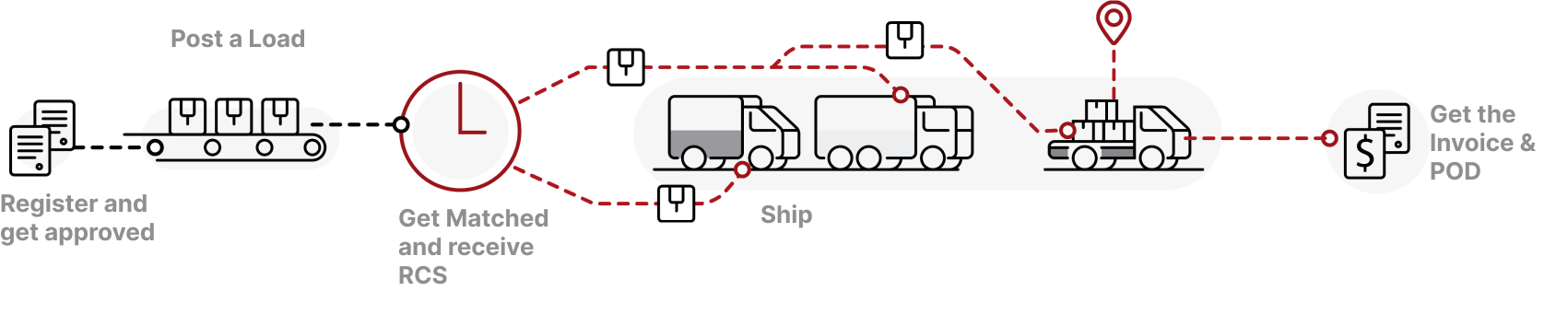

HOW IT WORKS

What is FTL Shipping?

Full truckload (FTL) refers to a type of shipping in which a single customer’s goods fill an entire trailer (full truck load), and the trailer is dedicated to that customer for the entire trip. In other words, the goods are not mixed with those of other customers, and the trailer is not unloaded and reloaded along the way.

FTL (full truckload) shipping option involves the use of a single truck to transport goods from a shipper to a consignee. FTL shipping is typically used for large, high-volume shipments that need to be delivered quickly and securely. In contrast to less-than-truckload (LTL) shipping, in which multiple shipments are consolidated on a single truck, FTL shipping involves the use of a dedicated truck for a single shipment.

FTL shipping is often used for large shipments that require a significant amount of space, or for shipments that are time-sensitive and need to be delivered quickly. It is also a good option for companies that have a consistent, high volume of shipments, as it allows them to negotiate discounted rates with carriers.

Benefits of Full Truck Load Shipping (FTL)?

The best way to transport large shipments, especially when you have strict delivery deadlines, is if you have enough volume to ship full truckloads. There are several advantages to using FTL shipping:

Speed: FTL shipments typically have a faster transit time than less-than-truckload (LTL) shipments, as they are not subject to the same loading and unloading delays.

Security: FTL shipments are less prone to loss or damage, as the goods are not handled as frequently and are not mixed with other shipments.

Cost: FTL shipping can be more cost-effective for large shipments, as the cost is based on the amount of space used rather than the weight of the shipment.

Flexibility: FTL carriers often offer a wide range of equipment options, such as refrigerated trailers or flatbeds, to accommodate different types of goods.

Carrier selection: It is important to choose a reputable and reliable carrier when using FTL shipping, as the goods are entrusted to a single company for the entire trip. It is a good idea to research carriers and get recommendations from other companies or industry professionals.

Disadvantages of FTL Shipping

Cost: FTL shipping may be more expensive than LTL shipping for smaller or lower-volume shipments, as the cost is based on the use of a dedicated truck for a single shipment.

Inflexibility: FTL shipping may not be as flexible as LTL shipping, as the shipper is committed to a single truck for the entire journey. This can make it more difficult to accommodate changes or delays in the shipping schedule.

Capacity constraints: FTL carriers may have capacity constraints, especially during peak shipping seasons or in certain regions. This can make it more difficult to secure capacity for shipments on short notice.

Limited service areas: FTL carriers may have limited service areas, especially for specialized equipment such as refrigerated trailers or flatbeds. This can limit the destination options for shipments.

Differences between FTL and LTL

FTL (full truckload) shipping and LTL (less-than-truckload) shipping are two options for transporting goods by truck. Here are some key differences between the two:

Size and volume of shipments: FTL shipping is typically used for large, high-volume shipments that fill an entire truck, while LTL shipping is used for smaller shipments that do not fill an entire truck.

Cost: FTL shipping is typically more expensive than LTL shipping for small or low-volume shipments, as the cost is based on the use of a dedicated truck for a single shipment. However, for large, high-volume shipments, FTL shipping may be more cost-effective than LTL shipping.

Transit time: FTL shipping is typically faster than LTL shipping, as the goods are not consolidated with other shipments and are transported directly to the destination.

Handling: FTL shipments are typically handled less frequently than LTL shipments, as they are not consolidated with other shipments and are not transferred between different trucks or warehouses.

Service áreas: FTL carriers may have more limited service areas than LTL carriers, as they specialize in transporting large, high-volume shipments.

Equipment: FTL carriers typically use a variety of equipment, including dry vans, refrigerated trailers, flatbeds, and specialized equipment such as hazardous materials trailers. LTL carriers may have a more limited range of equipment options, as they typically consolidate shipments on a single truck.

Freight classification: FTL shipments are typically classified based on the size and weight of the goods being shipped, as well as the type of equipment being used. LTL shipments are classified using a standardized system called the National Motor Freight Classification (NMFC), which assigns a class based on factors such as density, handling, stowability, and liability.

Freight consolidation: FTL shipments are not consolidated with other shipments, while LTL shipments are consolidated with other shipments in order to fill a truck. This can affect the handling and transit time of LTL shipments.

Carrier selection: FTL shippers typically have more flexibility in terms of carrier selection, as they can choose from a wider range of carriers that specialize in different types of equipment and service areas. LTL shippers may have more limited carrier options, as they are typically limited to carriers that offer consolidation services.

Tracking and visibility: FTL shipments are typically easier to track and have greater visibility, as they are not consolidated with other shipments and are not transferred between different carriers or warehouses. LTL shipments may have more limited tracking and visibility, as they are consolidated with other shipments and may be handled by multiple carriers.

Things to consider when using FTL Shipping

Documentation: A bill of lading (BOL) is an important document for FTL shipments, as it serves as a contract between the shipper and the carrier and serves as a document of title for the goods. The BOL should include detailed information about the goods being shipped, as well as the terms of the shipment.

Insurance: It is a good idea to purchase insurance for FTL shipments, as the goods are at a higher risk of loss or damage due to the longer transit time and handling.

Tracking: Most FTL carriers offer tracking services that allow shippers to monitor the progress of their shipments. This can be especially useful for time-sensitive shipments, as it allows shippers to identify any delays and make necessary adjustments.

Capacity: It is important to make sure that the carrier has the capacity to handle the shipment, as FTL carriers may not have as much flexibility as LTL carriers to adjust to changes in demand.

Freight class: The National Motor Freight Classification (NMFC) is a standard used to classify goods based on their characteristics, such as density, stowability, and handling. The NMFC assigns each type of goods a specific freight class, which is used to determine the rate for FTL shipments. It is important to accurately classify the goods being shipped in order to avoid overpaying for transportation.

Accessorial charges: In addition to the base rate for FTL shipping, carriers may charge additional fees for services such as liftgate service, residential delivery, or inside delivery. It is important to understand these charges and negotiate them with the carrier in advance.

Pallets: FTL carriers typically require shipments to be palletized in order to facilitate handling and loading. It is important to use properly sized and sturdy pallets that are suitable for the goods being shipped.

Load securement: It is important to properly secure the goods on the pallets in order to prevent damage during transport. This may involve using straps, shrink wrap, or other load securement methods.

Shipping labels: It is important to clearly label the goods being shipped, including the shipping destination and any special handling instructions. This will help ensure that the goods are delivered to the correct location and are handled properly.

Packaging:Packaging is important to protect the goods being shipped and to ensure that they are handled properly during transport. It is a good idea to use sturdy boxes or containers that are appropriate for the size and weight of the goods being shipped, and to use appropriate cushioning material to protect fragile items.

Temperature-controlled shipments:Some goods, such as food, pharmaceuticals, and chemicals, require temperature-controlled transport in order to maintain their quality. FTL carriers may offer refrigerated trailers or other temperature-controlled equipment for these types of shipments.

Hazmat shipments: Some goods, such as hazardous materials or dangerous goods, require special handling and transport due to the risks they pose. It is important to follow all applicable regulations when shipping these types of goods, and to work with a carrier that is experienced in handling hazmat shipments.

Cross-border shipping: FTL shipping can also be used for international shipments. It is important to understand the customs regulations and requirements of the destination country, as well as any additional documentation or fees that may be required.

Shipping lanes: FTL carriers typically operate on specific routes or shipping lanes, and they may offer discounted rates for shipments that align with these routes. It is a good idea to research the routes and rates of different carriers to find the best option for a specific shipment.

Lead time: FTL carriers may require more lead time to schedule shipments, as they need to coordinate the pickup and delivery of the goods. It is a good idea to plan ahead and allow enough time to schedule the shipment with the carrier.

Capacity constraints: FTL carriers may have capacity constraints, especially during peak shipping seasons or in certain regions. It is important to check the availability of carriers in advance and to plan accordingly.

Shipment visibility: Some FTL carriers offer advanced shipment visibility tools, such as real-time tracking or automated notifications, which can help shippers monitor the progress of their shipments and identify any potential issues.

Data análisis: Analyzing shipping data, such as transit times, carrier performance, and cost trends, can help shippers optimize their shipping operations and identify opportunities for cost savings.

Carrier relationships: Building strong relationships with carriers can be beneficial for FTL shippers, as it can lead to more favorable rates and service. It is a good idea to establish open lines of communication with carriers and to work together to resolve any issues that may arise.

Capacity planning: Planning ahead and forecasting shipping needs can help FTL shippers avoid capacity constraints and ensure that they have the resources they need to meet their shipping requirements.

Collaborative planning, forecasting, and replenishment (CPFR): This is a supply chain management approach that involves collaboration between suppliers, manufacturers, and retailers to optimize the flow of goods. It can be especially beneficial for FTL shippers, as it can help them coordinate with their partners to optimize their shipping operations.

Freight management systems: These are software systems that help FTL shippers manage their shipping operations, including rate negotiation, carrier selection, and tracking. They can help shippers streamline their shipping processes and improve efficiency.

Multimodal transportation

In some cases, it may be more cost-effective or efficient to use multiple modes of transportation, such as rail, air, or ocean shipping, in combination with FTL shipping. It is a good idea to consider the full range of transportation options when planning shipments.

Freight consolidation: In some cases, it may be more cost-effective to consolidate multiple small shipments into a single larger shipment, rather than shipping them separately. This can be especially beneficial for FTL shippers, as it allows them to take advantage of volume discounts and reduce the number of shipments they need to manage.

Carrier performance: It is important to monitor the performance of FTL carriers and to establish benchmarks and metrics to measure their performance. This can help shippers identify any issues and work with carriers to improve their performance.

Service level agreements (SLAs): SLAs are contracts between shippers and carriers that outline the terms of the shipping relationship, including service levels, rates, and terms of payment. It is a good idea to have clear and detailed SLAs in place when using FTL shipping.

Freight auditing: Freight auditing involves reviewing and verifying the accuracy of shipping invoices to ensure that shippers are being charged correctly. This can help shippers identify any billing errors or overcharges and negotiate with carriers to resolve them.

Sustainable shipping: Many FTL carriers are implementing sustainable practices, such as using fuel-efficient vehicles or reducing greenhouse gas emissions. It is a good idea for FTL shippers to consider the environmental impact of their shipping operations and to work with carriers that are committed to sustainability.

Freight forwarding: Freight forwarding is the process of organizing the transportation of goods on behalf of a shipper. FTL shippers may use freight forwarders to handle the logistics of their shipments, including carrier selection, customs clearance, and documentation.

Cross-docking: Cross-docking is a logistics strategy in which goods are transferred from one vehicle to another without being stored in a warehouse. This can be beneficial for FTL shippers, as it can reduce handling and storage costs and speed up the transportation process.

3PL (third-party logistics) providers: 3PL providers are companies that offer logistics services, such as warehousing, transportation, and supply chain management, to shippers. FTL shippers may use 3PL providers to outsource some or all of their logistics operations.

Supply chain visibility: Visibility into the supply chain can help FTL shippers identify bottlenecks and optimize their shipping operations. This may involve using technology such as real-time tracking or analytics to monitor the flow of goods.

Carrier management: It is important for FTL shippers to manage their relationships with carriers and to communicate regularly to ensure that shipments are running smoothly. This may involve regular meetings or performance reviews to discuss issues and identify opportunities for improvement.

Shipment optimization: There are a variety of tools and techniques that FTL shippers can use to optimize their shipments, such as route optimization software or load consolidation strategies. These can help shippers reduce transit times, minimize empty miles, and reduce costs.

Service level optimization: FTL shippers may need to balance the cost and transit time of different carriers and service levels in order to find the optimal solution for their shipments. This may involve evaluating factors such as delivery time, carrier reliability, and cost.

Freight rate benchmarking: Benchmarking freight rates can help FTL shippers compare the rates of different carriers and identify opportunities for cost savings. This may involve collecting data on rates for similar shipments and comparing them to market rates.

Capacity planning: It is important for FTL shippers to have a clear understanding of their capacity needs and to plan ahead in order to avoid capacity constraints. This may involve forecasting shipping demand, negotiating with carriers, and using tools such as load boards to find available capacity.

Carrier selection: Choosing the right carrier is an important decision for FTL shippers, as the carrier is responsible for the entire journey of the shipment. It is a good idea to research carriers and compare their rates, service levels, and equipment options in order to find the best fit.

Carrier performance: It is important for FTL shippers to monitor the performance of their carriers and to identify any issues or opportunities for improvement. This may involve collecting and analyzing data on transit times, delivery accuracy, and other performance metrics.

Carrier relationships: Building strong relationships with carriers can be beneficial for FTL shippers, as it can lead to more favorable rates and service. It is a good idea to establish open lines of communication with carriers and to work together to resolve any issues that may arise.

Carrier management: Managing carrier relationships can be a complex task, especially for FTL shippers with a large number of carriers. It is a good idea to use tools such as carrier portals or transportation management systems (TMS) to manage carrier relationships and streamline communication.

Carrier scorecards:Carrier scorecards are tools that help FTL shippers track the performance of their carriers and identify areas for improvement. Scorecards may include metrics such as on-time delivery, damage rates, and customer service.

Carrier contracts: Carrier contracts are legally binding agreements that outline the terms of the shipping relationship, including rates, service levels, and terms of payment. It is important for FTL shippers to carefully review and negotiate these contracts.

Freight audit and payment: Freight audit and payment involves reviewing and verifying the accuracy of shipping invoices and making payments to carriers. It is important for FTL shippers to have a system in place to manage this process efficiently, in order to avoid billing errors or disputes.

Freight bill factoring: Freight bill factoring is a financial service that allows FTL shippers to sell their unpaid invoices to a third party at a discount in order to receive immediate payment. This can be a useful option for shippers that need to manage their cash flow or that have long payment terms with their carriers.

Capacity planning: It is important for FTL shippers to have a clear understanding of their capacity needs and to plan ahead in order to avoid capacity constraints. This may involve forecasting shipping demand, negotiating with carriers, and using tools such as load boards to find available capacity.

Shipment optimization: There are a variety of tools and techniques that FTL shippers can use to optimize their shipments, such as route optimization software or load consolidation strategies. These can help shippers reduce transit times, minimize empty miles, and reduce costs.

Service level optimization: FTL shippers may need to balance the cost and transit time of different carriers and service levels in order to find the optimal solution for their shipments. This may involve evaluating factors such as delivery time, carrier reliability, and cost.

When to use FTL instead of LTL

The heavier your shipment is, the higher your freight quote will be. If the goods you want to ship are on a pallet or bagged in a container (whether it’s LTL shipping or FTL shipping), you can easily determine their weight.

You just need to weigh all items individually and then add all the weights to get the whole shipment’s weight. While calculating the shipment weight, don’t forget to add the weight of the pallet to the total weight. A typical pallet weighs around 40 lbs. If your freight is in more than one pieces, simply weigh each piece individually and add up all weight to calculate the shipment’s weight.

The next step is determining the size of the shipment. If you have a single-piece shipment enclosed in a crate, simply measure the length, width, and height of the crate. It will give you the size of your shipment. However, if your shipment is a multi-piece, you need to measure each piece’s dimensions individually and add all the dimensions together to get your shipment’s size.

Once you have determined the size and weight of your shipment, it will be easy for you to figure out what shipping mode you require – LTL shipping or FTL shipping.

FTL Shipping Conclussion

FTL (full truckload) shipping is a transportation option for companies that have a large volume of goods to be shipped. In FTL shipping, the goods are transported in a single truck, rather than being consolidated with other shipments as in less-than-truckload (LTL) shipping. FTL shipping is typically more cost-effective and faster than LTL shipping for large, high-volume shipments that need to be delivered quickly and securely.

Overall, FTL shipping is a good option for companies that have a consistent, high volume of large shipments that need to be delivered quickly and securely. It is important to carefully consider the size and nature of the goods being shipped, as well as the destination and transit time, when deciding whether to use FTL shipping.

Improve now the efficiency of your supply chain.

Book a free consultation with a Fr8App Expert and optimize your results today.